Dmsons Metal was founded with the ultimate principle of understanding and fulfilling the requirements of our customers. We firmly believe that our success is driven by maintaining high standards of quality, ensuring timely delivery, offering economical pricing, and delivering exceptional customer service. Through years of dedication and continuous improvement, we have established ourselves as a renowned name in various industries across India. Our commitment to strict quality controls and unwavering dedication to meeting client expectations have fostered strong and enduring relationships with our valued customers.

Experience the ease and simplicity of precision cutting and inspection with Dmsons Metal.

Metal cutting and inspection play a crucial role in the manufacturing procedure of many industries. This requires high accuracy and regular quality checks to guarantee efficient delivery to our customers. At Dmsons, we have been perfecting the science and craft of precision cutting and inspection with the help of state of the art technology and the expertise of our skilled workforce.

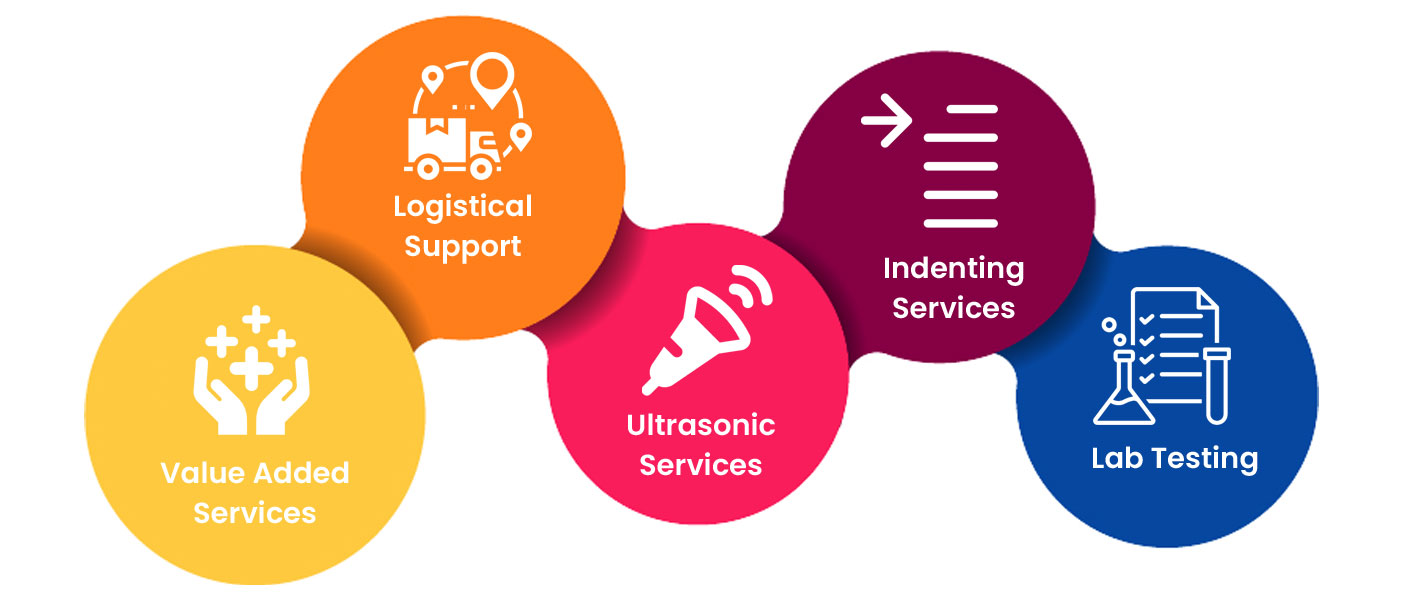

Our value added services include sheet metal rolling, cutting and bending.

Sheet Metal Rolling: – It involves passing of metal stock through one or more pairs of rolls to decrease the thickness and make the thickness uniform according to precise dimensions. This metal can be available in flat pieces or coiled strips. Sheet metal can be cut and bent into several applications like ductwork, machine components, architectural column covers, wall coverings, tank bodies and machine guards are just to name a few. Several manufacturing processes of sheet metal include rolling, bending, curling, incremental sheet forming, laser cutting, perforating, press brake forming, punching, spinning and stamping.

Sheet Metal Cutting: – This service is a main classification for many different press working operations. Metal cutting includes the separation of metal sheets in certain areas. The most common cutting processes are ‘punching, piercing and shearing processes’. Clean cut edges, precise tool guidance, minimal installation space due to integrated damping of cutting impact and optimal scrap management are instrumental to deliver you maximum benefits.

Types of Cutting: –

Sheet Metal Bending: – Bending is the forming of sheet metal by application of force, which applies pressure on a certain length of material either at a specific point or linear as a uniformly distributed weight. Our procedure is carried out with press brakes, roll bending machines and embossing/coining machines. There are many diverse industries that benefit from the sheet metal forming process every day. For example, metal fabrication is used in the automotive industry to create fenders, hoods and doors. The most common applications of bent sheet metal parts are as automobile & aircraft panels, housings, cabinets, etc. It is also used in the home appliance industry to create freezers, hoods and sinks. Metal bending is mainly practiced on austenitic stainless steel, low alloy aluminium & copper, mild steel and brass.

Streamline your logistical needs with our assistance, ensuring timely procurement and delivery.

At Dmsons Metal Pvt. Ltd., we deeply appreciate the significance of your business and the effort you put into it. We understand that scheduling and timelines are crucial aspects of any business operation. Therefore, we offer comprehensive logistical support to ensure flexibility in even the most complex operations. With our expertise, we provide official documentation for transportation and strive to minimize waiting times for all deliveries. You can rely on us to optimize your logistical requirements and ensure smooth and efficient operations for your business.

Ensuring Product Quality with UT Testing

UT (Ultrasonic Testing) is an essential method employed by Dmsons Metal to guarantee the highest level of product quality. By utilizing ultrasonic waves, this testing procedure detects and eliminates any inconsistencies in metal-related products, meeting and exceeding customer satisfaction. During the process, a specialized machine scans the metal product at designated scan and sampling intervals. If no inconsistencies are found that exceed the allowable limits specified in the UT standards, the product successfully passes the test. It is important to note that the stringency of the specifications directly impacts the cost of testing and the materials used. With UT testing, we prioritize precision and reliability to deliver superior products that meet the highest quality standards.

Our scope of services ranges from import, stocking and dealership in high quality steel and metal

At Dmsons Metal, our range of services encompasses the import, stocking, and dealership of high-quality steel and metal products. As part of our sourcing process, we establish partnerships with esteemed clients from countries such as Germany, Japan, Korea, Russia, Ukraine, Indonesia, China, and Iran. This involves facilitating transactions between buyers and sellers in the metal and steel industry. Additionally, our indenting service representatives offer assistance in temporary warehousing and storage solutions. We also take charge of overseeing and monitoring the shipping process, ensuring a streamlined experience for our customers. Our dedicated team locates and procures goods on behalf of our clients, securing the best possible purchase prices and shipping terms. At Dmsons Metal, we aim to provide comprehensive solutions that meet your metal and steel needs efficiently and effectively.

All products are processed with thorough quality checks and lab tests

Dmsons Metal prioritizes thorough quality checks and lab tests for all our products. In various industries, it is essential that metal parts are safe to handle, reliable, and compliant with regulatory standards. Metal inspection, analysis, and testing play a vital role in ensuring product safety, reliability, and answering questions related to material selection, production, or product failure. Our highly experienced engineers and technicians specialize in metal lab testing, providing reliable services. We conduct lab testing for our wide range of products, and our technicians are well-equipped to handle test material parts of all shapes, sizes, and quantities safely. Metal testing verifies the characteristics, properties, and flaws of the metal, ensuring that the metal parts can operate safely and comply with the required accreditation. At Dmsons Metal, we prioritize the quality and integrity of our products through comprehensive lab testing processes.

Address: 502, Peninsula Heights

Juhu Lane, Andheri West

Mumbai 400 058

AN ISO 9001:2015 CERTIFIED COMPANY