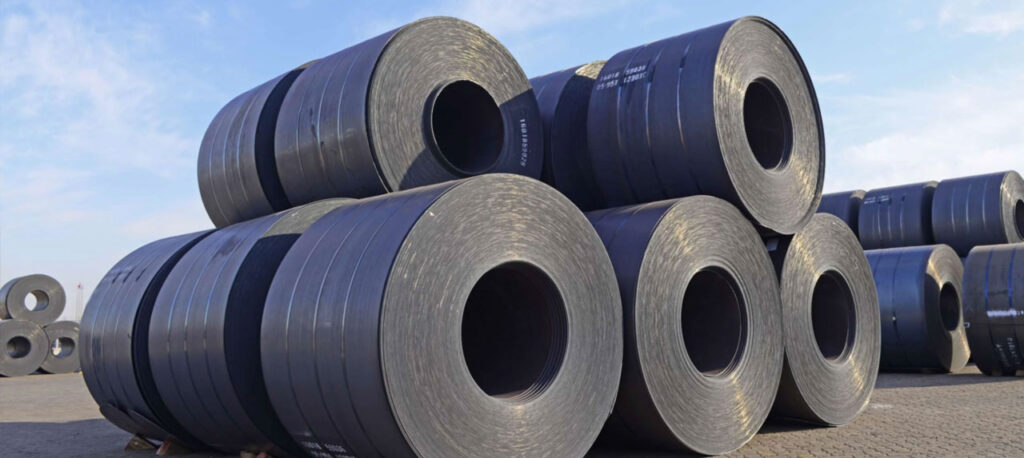

Hot Rolled Coils play a pivotal role in various industries due to their exceptional properties and applications. They are an essential component in the manufacturing sector, construction industry, and numerous other fields. This comprehensive guide will delve into the world of Hot Rolled Coils, providing insights based on first-hand knowledge and credible sources. Let’s explore the fascinating world of Hot Rolled Coils and discover their wide-ranging uses.

Hot Rolled Coils: An Overview

Hot Rolled Coils (HRCs) are steel coils that undergo the hot rolling process, wherein steel is passed through rollers at high temperatures. The process enhances the steel’s mechanical properties, making it more malleable and ductile. The steel is heated to above the recrystallization temperature, enabling it to be shaped into various forms without compromising its strength. The resulting Hot Rolled Coils find extensive applications across industries.

Properties of Hot Rolled Coils

Hot Rolled Coils possess several essential properties that make them highly sought-after in industrial applications. These properties include:

- Weldability: HRCs offer excellent weldability, enabling efficient joining of different components during manufacturing processes.

- Tensile Strength: The hot rolling process imparts impressive tensile strength to the coils, making them robust and durable.

- Ductility: HRCs exhibit high ductility, allowing them to be easily formed into different shapes without fracturing.

- Surface Finish: The surface of Hot Rolled Coils is relatively rough, making them ideal for applications where surface aesthetics are not a primary concern.

- Cost-Effective: Hot Rolled Coils are cost-effective compared to their cold-rolled counterparts, making them a preferred choice in various projects.

Applications of Hot Rolled Coils

Hot Rolled Coils find diverse applications across multiple industries, including:

- Pipelines: Hot Rolled Coils are used in the production of oil and gas pipelines, where their high tensile strength and weldability are essential.

- Construction: In the construction sector, HRCs are utilized in the fabrication of beams, columns, and structural components.

- Shipbuilding: Shipbuilders rely on HRCs to construct hulls and other structural elements for ships and marine vessels.

- Automotive: HRCs are used in the manufacturing of automotive components, such as chassis, frames, and wheels, due to their strength and formability.

- Appliances: Hot Rolled Coils are found in household appliances like refrigerators, stoves, and washing machines.

Advantages of Hot Rolled Coils

Hot Rolled Coils offer numerous advantages over other forms of steel, making them a popular choice for various applications:

- Strength and Durability: HRCs exhibit high tensile strength and durability, ensuring longevity and reliability in various applications.

- Versatility: The malleability and formability of HRCs allow them to be shaped into different profiles, meeting specific project requirements.

- Time-Efficient: The hot rolling process is quicker than cold rolling, leading to faster production times.

- Cost-Effective Production: Hot rolling is a more economical process compared to cold rolling, making HRCs more cost-effective.

- Recyclability: Hot Rolled Coils are recyclable, promoting sustainability and reducing environmental impact.

Factors Affecting the Quality of Hot Rolled Coils

Several factors influence the quality of Hot Rolled Coils. Manufacturers must consider these factors to ensure superior product quality:

- Chemical Composition: The chemical composition of the steel used for HRCs impacts their properties and applications.

- Temperature Control: Precise temperature control during hot rolling is crucial to achieve the desired mechanical properties.

- Cooling Rate: The cooling rate after hot rolling influences the microstructure and overall quality of the coils.

- Rolling Speed: The speed at which the steel passes through the rollers affects the surface finish and uniformity of the coils.

Utilizing Hot Rolled Coils in the Manufacturing Process

In the manufacturing sector, Hot Rolled Coils are an integral part of the production process. They are used in various ways, such as:

- Strengthening Structures: Hot Rolled Coils are used to reinforce structures, providing them with enhanced strength and stability.

- Forming and Bending: HRCs are shaped and bent into specific forms to create components used in different industries.

- Casting and Forging: Hot Rolled Coils serve as starting materials for casting and forging processes, enabling the creation of complex parts.

- Welding and Joining: The excellent weldability of HRCs allows for efficient joining of steel components during fabrication.

Safety Considerations when Handling Hot Rolled Coils

Working with Hot Rolled Coils requires adherence to safety protocols to avoid accidents and injuries. Some essential safety considerations include:

- Protective Gear: Workers should wear protective gear, such as gloves and safety glasses, while handling HRCs.

- Proper Lifting Techniques: Using appropriate lifting equipment and techniques to handle heavy coils safely.

- Training and Awareness: Providing training to workers about the potential hazards and safety precautions related to Hot Rolled Coils.

- Storage and Handling: Storing HRCs in designated areas and using proper handling equipment to minimize the risk of accidents.

Conclusion

Hot Rolled Coils are a versatile and essential material used in various industries for their strength, formability, and cost-effectiveness. Understanding their properties, applications, and safety considerations is vital for manufacturers and users alike. By following sustainable practices, we can ensure the responsible use of Hot Rolled Coils while minimizing their environmental impact. Embrace the potential of Hot Rolled Coils and unlock their numerous benefits in your projects.