As you embark on a new construction or renovation venture, one of the pivotal decisions you face is selecting the appropriate materials. Among the most crucial materials utilized in projects involving flooring, stairs, and vehicle trailers are steel plates, particularly Chequered Plates. However, with a plethora of options available, how do you determine the ideal one for your specific project?

This blog post aims to provide you with a comprehensive guide on selecting the best Chequered Plate for your undertaking. We will closely examine the various types of chequered plates, their grades and sizes, and the essential factors to consider while making the right choice.

What is Chequered Plate?

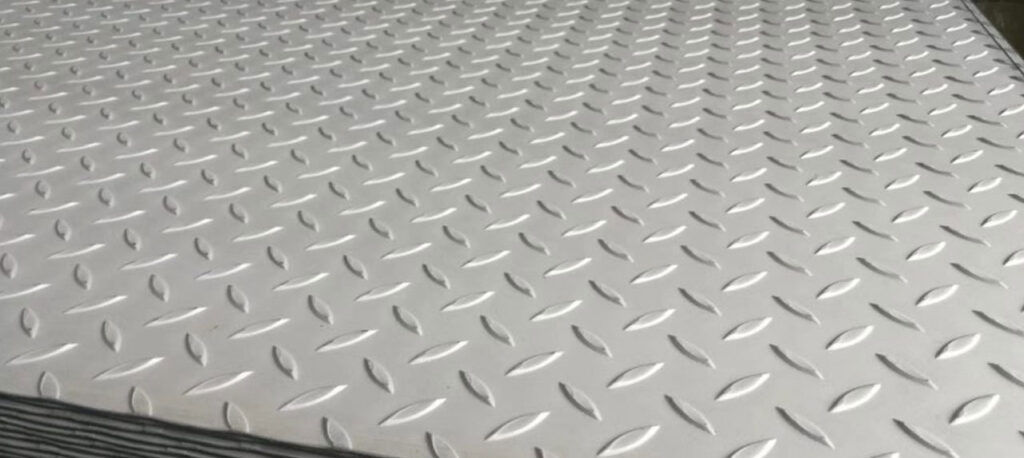

Chequered Plate is a steel sheet with a design of raised diamonds or lines on the surface. It is usually used for ramps, walkways, platforms, stair treads, and other architectural and structural purposes. The chequered plate offers greater strength to other metals due to its unique diamond-shaped pattern, which helps evenly distribute weight over a larger area, making it much more firm than regular steel plates. Furthermore, it has an aesthetically pleasing look which can enhance any construction project in terms of appearance.

Types of Chequered Plates

Chequered Plates are available in two primary types: hot-rolled and cold-rolled. The distinction between the two lies in their manufacturing processes. Hot-rolled plates are created by subjecting the steel to exceedingly high temperatures, whereas cold-rolled plates are produced by rolling the steel at room temperature. Consequently, hot-rolled plates have a rough surface finish, while cold-rolled plates boast a smooth finish.

Grades and Sizes of MS Chequered Plates

Chequered Plates are available in various grades, each possessing distinct properties that render them suitable for diverse applications. Among the most common grades are A36, IS 3502, and S355M. These grades offer specific characteristics to cater to different project requirements.

In terms of sizes, chequered plates can vary based on their intended application. Typically, they are found in varying thickness between 5MM-12MM, width of 1250-1500MM and length of 5000-6300MM. However, some suppliers such as Dmsons Metal Pvt. Ltd. offer the option of customized sizes to meet specific project needs.

Factors to Consider When Choosing the Best MS Chequered Plate

When choosing the optimal Chequered Plate for your project, several critical factors warrant consideration. Initially, assess the project’s load capacity requirements to determine the appropriate plate thickness. Thicker chequered plates typically exhibit better load-bearing capabilities.

Moreover, take into account the plate’s intended environment of use. For outdoor applications, prioritize plates with corrosion-resistant properties, ensuring they can withstand environmental elements such as rain, heat, and humidity.

Thirdly, factor in the overall project cost. While some suppliers may offer cheaper plates, it’s crucial to assess their durability and suitability for the intended purpose, as opting for subpar plates may lead to increased costs in the long term.

Finally, ensure you source the Chequered Plate from a reliable and reputable supplier with a proven track record of delivering quality products. By choosing a dependable supplier, you can have confidence in the plate’s quality and performance for your project.

Conclusion

The process of choosing the ideal Chequered Plate for your project holds significant importance in ensuring optimal performance and meeting your specific needs. By taking into account factors such as the type, grade, size, load capacity requirements, environmental suitability, costs, and the reliability of the supplier, you can make a well-informed decision.

Considering these crucial aspects will empower you to secure the best-fitting Chequered Plate that aligns perfectly with your project’s demands. With this comprehensive guide and Dmsons Metal at your disposal, you can proceed with confidence, knowing that you have selected the most suitable Chequered Plate for your project’s success.